Introduction to Lean Construction

Lean construction is a methodology that promotes efficiency and quality while minimizing waste. As a result, lean construction creates a positive impact on the environment. Additionally, it helps construction companies continuously improve which leads to maximizing customer value and increasing client satisfaction. Some benefits of lean construction include reducing costs, increasing productivity, and minimizing construction times. This relationship-based method promotes collaboration and accountability. In turn, stakeholders are required to work together as a team.

Lean Construction Applications

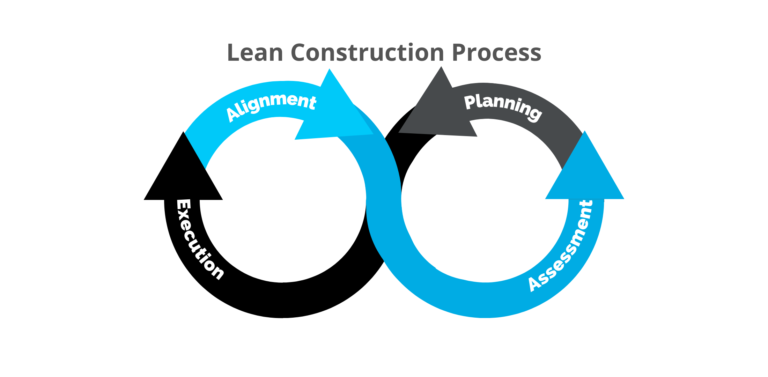

You have probably heard about the term “lean construction.” However, you may wonder what lean construction actually looks like in real life. The first step in designing strategies and tactics is to identify the goal. Here are some examples of lean construction strategies and tactics that can be implemented in an organization to achieve various goals. Some possible goals your organization may want to reach are alignment, assessment, planning, and execution.

Goal: Alignment -Help your team identify where they fit in.

Lean construction helps your team align and identify where each person fits in the whole picture. One strategy could be engaging employees in problem-solving by hosting team-building and training exercises regularly. Another helpful strategy is to apply methodologies to the entire construction organization by extending conversations across the company. Getting everyone involved helps each person realize their strengths and their contributions.

Goal: Assessment – Help managers assess constraints and requirements.

Lean construction can help managers assess constraints and requirements. One strategy is constraint analysis by creating a constraint log. After constraints are taken into account, managers can determine what the work commitment is. Also, when constraints are identified they can be communicated and understood by everyone involved. Assessment of constraints and requirements makes lean construction processes more proactive than reactive.

Goal: Planning – Help managers identify the steps to complete the project

Lean construction can help managers identify the steps to complete the project. Since this methodology maximizes benefits and minimizes waste, it helps people only use what is needed. To accomplish this, strategic planning and action are both crucial. By eliminating the unnecessary, managers will have a plan with the steps required to complete the project.

Goal: Execution – Increase productivity in key focus areas.

Lean construction can help your team execute plans in an intentional way. One strategy to consider is innovating new ways of doing work by encouraging collaborative work wherever possible. Collaborating will fuel ideas. Another strategy is to improve workflow and coordination throughout the whole project by making continuous improvements as a regular activity.

Learn More

Looking to use lean construction methodologies at your construction company? Contact us to discuss how we can help you.